Last update: March 2023

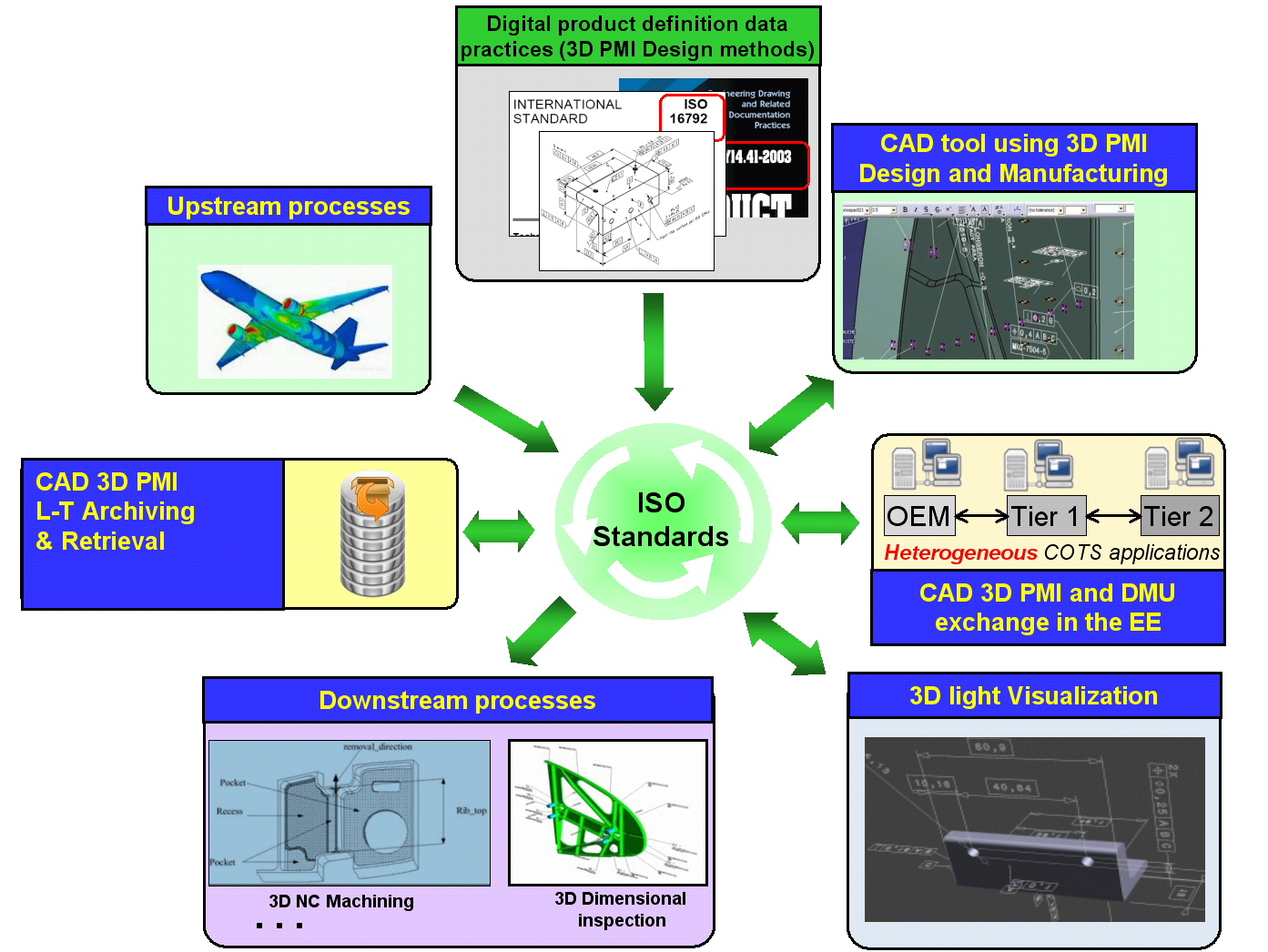

The objective of the “CAD 3D Mechanical interoperability” working group is to ensure the coordination and the consistency of all standardisation activities related to “CAD 3D Mechanical” interoperability, including Product Manufacturing Information (PMI).

This working group is part of the ASD SSG “PLM interoperability” domain.

The recommendations of the working group cover product information interoperability for the full life cycle of the mechanical part development, from specifications to maintenance and dismantlement. It covers all the interoperability functions based on open standards, such as:

- integration between heterogeneous authoring applications (upstream, downstream, ...)

- communication with the extended enterprise or with the customers,

- visualisation,

- long term archiving and retrieval,

- data quality,

- and migration.

Scope

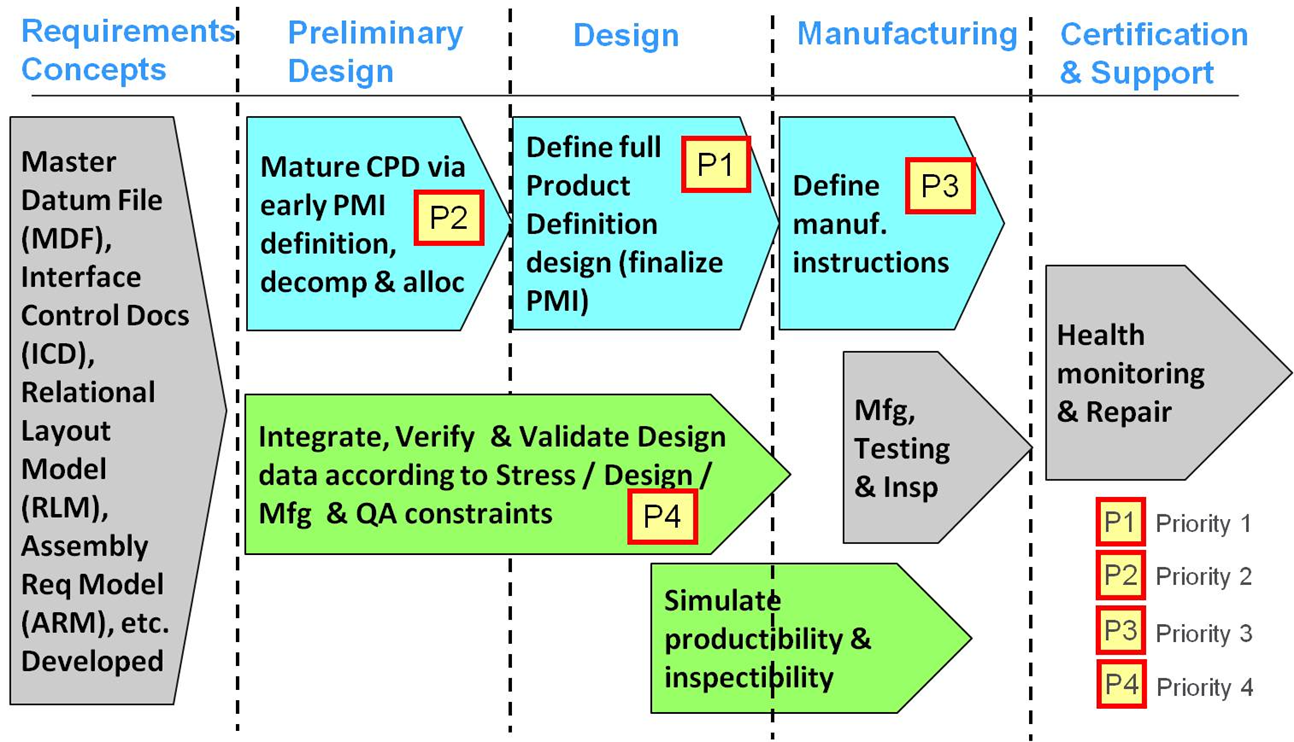

The following picture describes a generic process of development of mechanical part.

Nota: Same figure than for the AIA – ASD Stan LOTAR “3D PMI” working group

List of use cases

The following table list the use cases to be supported by the international standards for 3D geometry and Mechanical information interoperability.

|

CAD 3D PMI "graphic" |

|

CAD 3D PMI "graphic" for visualisation |

|

CAD 3D PMI "graphic" for long term archiving and retrieval for certification |

|

CAD 3D PMI "graphic" for interface control model (ICM) exchange |

|

CAD 3D with PMI "semantic" |

|

CAD 3D with PMI "semantic" for down stream reuse |

|

CAD 3D with PMI "semantic" for migration |

|

CAD 3D with PMI "semantic" for manufacturing and repairs |

|

CAD 3D with PMI "semantic" for assembly and installation |

|

CAD assemblies and 3D simplified |

|

CAD assemblies and 3D simplified for bid |

|

CAD assemblies and 3D simplified for DMU review/clash detection |

|

CAD 3D PMI "parametric" |

|

CAD 3D PMI "parametric" for upstream reuse (CAD <=> CAE) |

|

CAD 3D PMI "parametric"for down stream reuse (CAD-CAM) |

|

CAD 3D PMI "parametric" for long term archiving and retrieval (for reuse) |

ASD SSG 5 years vision

The 5 years vision of the ASD SSG “Mechanical interoperability” working group is set up on three principles:

1) Mechanical interoperability ensured by the availability of business requirements, use cases, public test cases, ISO information model, recommended practices and interoperability test rounds of CAD vendors COTS standards interfaces.

The operational use of Mechanical interoperability standards by the A&D industries requires the availability of:

- Business requirements of the industry,

- Use cases for Mechanical interoperability, supporting A&D business needs and priorities,

- Public test cases for Mechanical interoperability, illustrating the use cases,

- International standards for Mechanical Information models,

- International and/or European recommended practices based on use cases, detailing the implementation of the ISO Mechanical information model,

- Interoperability test rounds of the standardised Mechanical interfaces and services of the different PLM vendors, through the participation in the CAx Implementer Forum.

2) Reliable ISO Information models for Mechanical interoperability.

The ASD SSG recommends the choice of a limited number of core harmonised ISO 10303 Application Protocols, having interdependencies properly specified and managed through the time, completed by other relevant ISO 3D visualisation standards..

The ASD SSG recommends the use of ISO 10303 AP 242 as the cornerstone standard for mechanical information interoperability (Ref. ASD SSG Feb. 2015 statement).

AP242 is developed in consistency with:

- STEP AP 238 edition 2 “Model based integrated manufacturing” - More information on www.ap238.org.

- STEP AP 209 edition 2 “Multidiciplinary Analysis and Design” - More information on www.ap209.org.

Planned operational use of ISO standards for Mechanical interoperability and long term archiving:

|

|

Planned operational use |

|

|

Short term 2023-2024

|

Midterm 2025-2026

|

Long Term +2027

|

|

Exchange - migration

|

ISO 10303 STEP AP 242 ed.3

|

ISO 10303 STEP AP 242 ed.4 (N1)

|

ISO 10303 STEP AP 242 ed.4 (N1)

|

|

ISO 14306 JT ed.2

|

ISO 14306 JT ed.3 (N2)

| ISO 14306 JT ed.3 (N2)

|

|

LT Archiving and Retrieval

|

ISO 10303 STEP AP 242 ed.3

|

ISO 10303 STEP AP 242 ed.4 (N1)

|

ISO 10303 STEP AP 242 ed.4 (N1)

|

|

Visualisation

|

ISO 10303 STEP AP 242 ed.3

|

ISO 10303 STEP AP 242 ed.4 (N1)

|

ISO 10303 STEP AP 242 ed.4 (N1)

|

|

ISO 14306 JT ed.2

|

ISO 14306 JT ed.3 (N2)

| ISO 14306 JT ed.3 (N2)

|

|

ISO 32000-2

|

ISO 32000-2

| ISO 32000-2

|

(N1) ISO 10303 STEP AP242 ed.4 is in preparation.

(N2) ISO 14306 (JT) ed.3 is in preparation.

3) Contribution to the development and use of the NAS / EN 9300 1xx family, for Long Term Archiving and Retrieval of Mechanical information.

The LOTAR standards define Process, use cases, validation and verification rules for long term archiving and retrieval of mechanical information.

|

Part |

Title |

|

NAS / EN 9300-100 |

Common concepts for L-T Archiving and retrieval of CAD 3D mechanical information |

|

NAS / EN 9300-110 |

L-T Archiving and Retrieval of CAD 3D Explicit geometry information |

|

NAS / EN 9300-115 |

L-T Archiving and Retrieval of Explicit CAD assembly structure |

|

NAS / EN 9300-120 |

Long Term Archiving & Retrieval of CAD 3D Explicit Geometry with Graphic Product Manufacturing Information (PMI) |

|

NAS / EN 9300-121 |

Long Term Archiving & Retrieval of CAD 3D Explicit Geometry with PMI Semantic representation. |

|

NAS / EN 9300-125 |

Long Term Archiving & Retrieval of Explicit CAD assembly structure with Graphic Product and Manufacturing Information (PMI) |

Related recommended practices

CAD 3D Mechanical Interoperability WG

CAD 3D Mechanical Interoperability WG